In House Finite Element Analysis Capabilities

Finite Element Analysis (FEA) is an engineering simulation discipline that has its roots in the aerospace industry, during the 1950’s. Since that time the discipline has ‘come into its own,’ spurred by the progress of computer hardware and software technologies, coupled with aggressive competition between software companies specializing in FEA products.

While FEA applies to many engineering fields, it is most often understood in terms of structural analyses for mechanical engineers. A typical question addressed by FEA analysts would be, “Will a part fail under such-and-such loading (forces and restraining) conditions?”

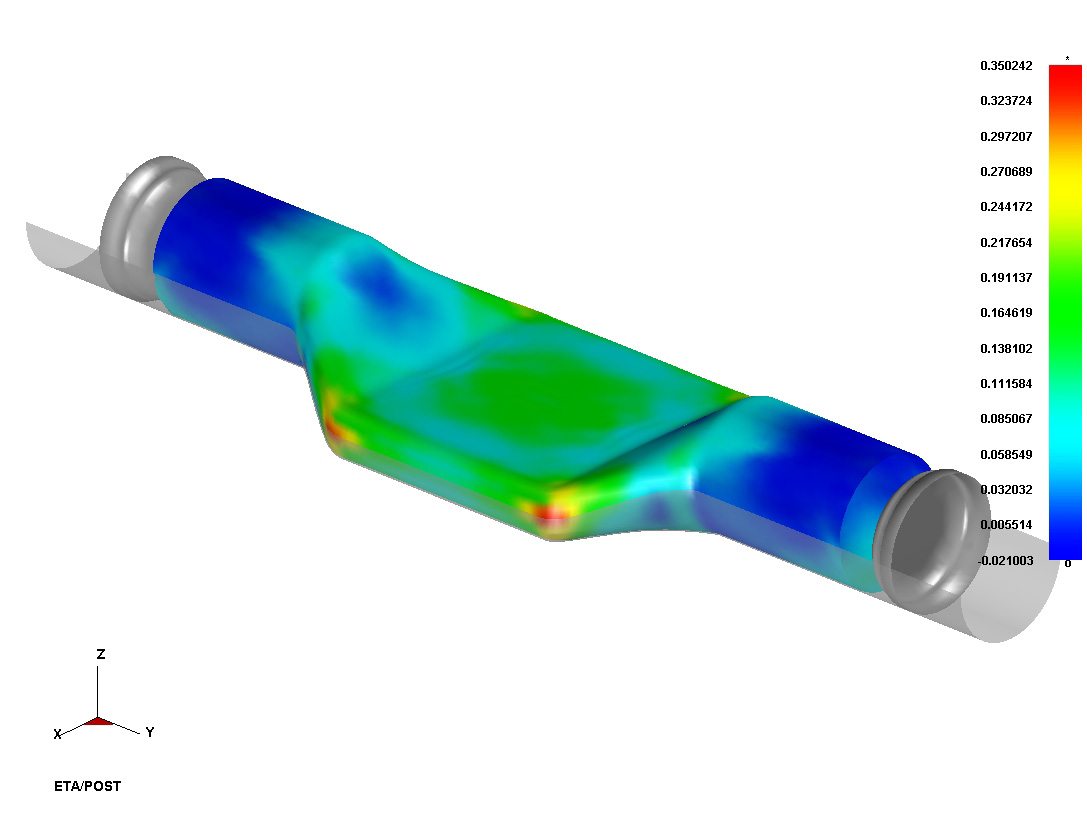

Our company is a little different in that the questions we address by our FEA simulations. Our simulations answer questions like, “what are the prestresses caused by the manufacturing process?” Or, “Will the prestresses of the manufacturing process cause failure in the client’s part under the conditions specified by the client?” And finally, there is always the iterative process of changing a manufacturing process within the virtual world of a given finite element analysis, to perfect the process.

One might ask, “Why not just do actual experiments?” We would of course arrange to do such tests for our clients. However, the problem with the more established ‘Make and Break,’ approach compared to FEA is additional (1) timing and (2) expenses loaded onto a given project. These factors make it prohibitive for project engineers to rely exclusively on laboratory testing. FEA usage cuts down on the time in the design phase of a project, a phase which affects all others in the product development process.

As an added benefit – when FEA analyses can be standardized (as we have with our hydroforming simulations), significant time and cost savings can be achieved that would not be possible using the old ‘Make and Break’ product testing methodology.

For further information about how our Finite Element Analysis capabilities may achieve cost savings and enhanced structural performance for your products, please contact us.

Leave a Reply