Hydroformed Components Revive Classic Cars

Hydroformed automotive parts are showing up on a lot of new car models – the Ford Fusion, the 2014 Chevrolet Corvette and the Chevrolet Silverado, for example – but new cars are not the only vehicles sporting these superior hydroformed components, older models can enjoy the many benefits too.

A New York Times article describes how Jonathan Ward uses hydroformed components to restore and recreate classic cars and trucks. His goal is to retain the appeal of the design while improving the structural integrity. Ward accomplishes this many times by replacing orignal parts with hyrdroformed parts which can be custom-made to the exact specifactions needed. Ward credits this new technology with making it possible to custom-restore classic models.

“You couldn’t have done this 10 years ago,” he said, adding that laser scanning had made it possible to build just about any shape out of modern materials using hydroforming or an English wheel. “Once you can track and control forms, you can go back and recreate something.”

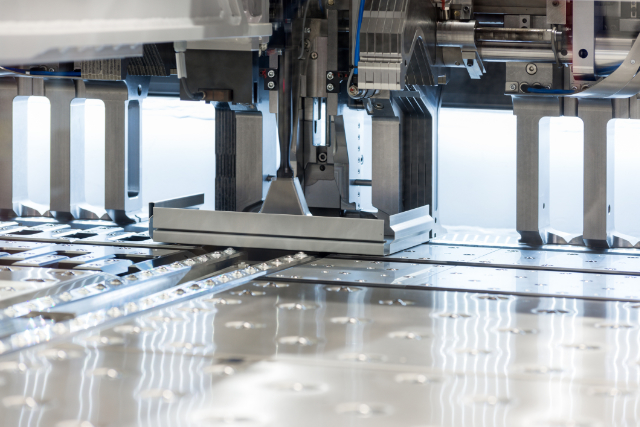

Hydroforming is a perfect partner for the automotive industry in creating lightweight, durable parts that are thinner yet stronger. Hydroforming allows for creating shapes and bends without the need for welded joints, leading to an overall sturdier construction. Using hydroformed components generally removes the need for heavy materials that can endure the stamping, welding, cleaning, etc. which add unnecessary weight to the vehicles, the lighter hydroformed components are generally stronger and much more efficient in the manufacturing process.

At American Hydroformers, we use the latest advances in hydroforming technology. We offer industrial laser cutting, stencil work and tube forming. Whether you’re restoring a classic car or need complete assembly level automotive part fabrication, we can help you find the right metal fabricating solution for your specific needs.

Contact us today for more information.

Error: Contact form not found.

Leave a Reply