Tube Hydroforming is Beneficial

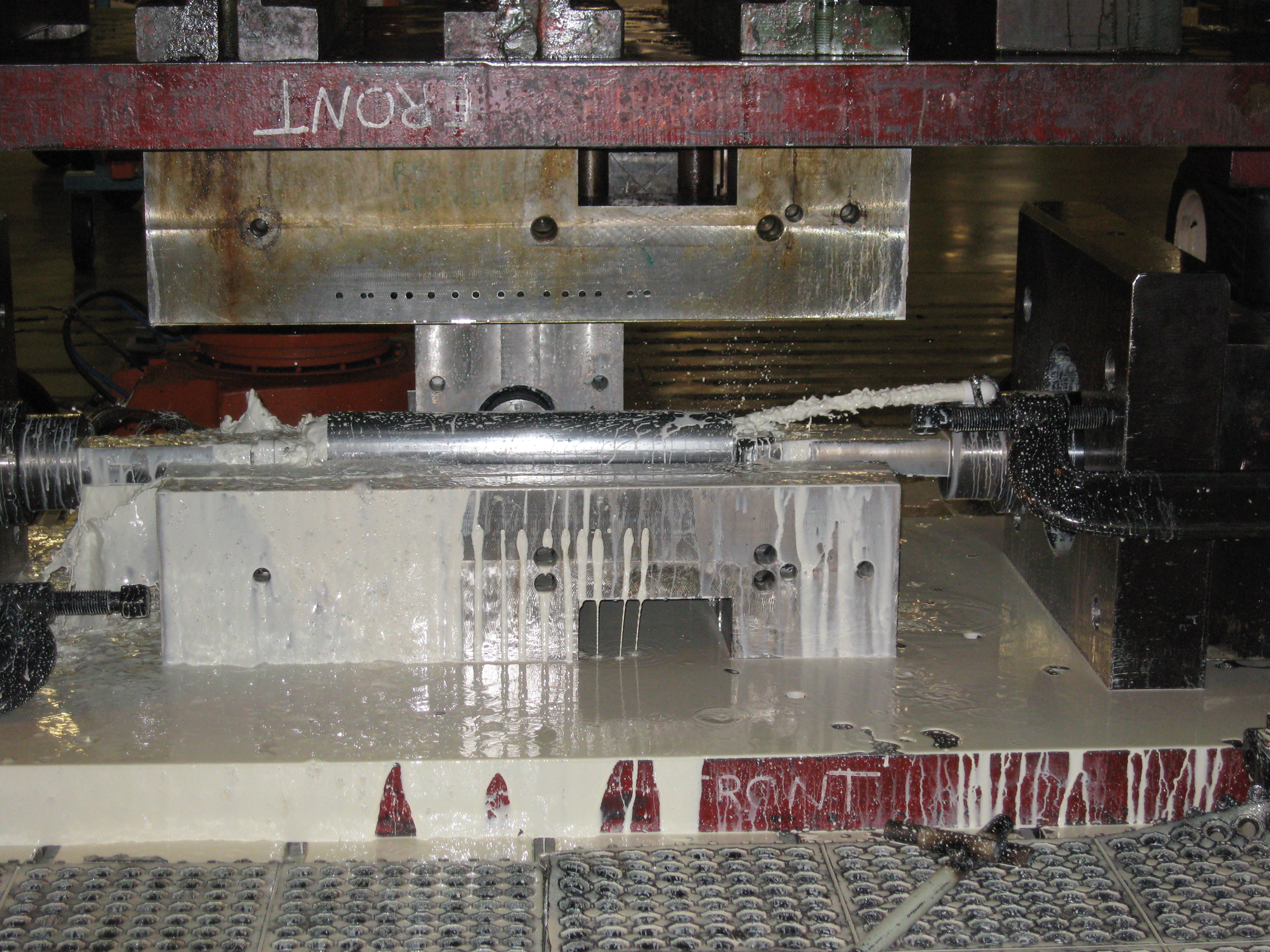

First referenced from an early 1900s process, tube hydroforming is constantly improving parts and workplace functionality. Tube hydroforming is a metal forming process where pressurized fluids form the workpiece into a shape. This technique is only now really starting to take off, though the concept of tube hydroforming has been around a while.

Until the 1980s, there was no way to economically build a tubular part with dimensional stability, design flexibility, and hole-making ability, so tubes had to be welded together from stamped parts. When tube hydroforming was fully realized and established, it satisfied a long-awaited need in the industry, which explains why tube hydroforming has gained rapid acceptance throughout the USA.

Tube hydroforming offers many benefits as compared to conventional forming techniques. The ability for deeper draws and closer control of perimeters increases part stability and prevents wrinkles and tearing. Tube hydorforming creates a part that is stiffer, less likely to have defects, and is resistant to buckling. Hydroforming replaces the stamping assemblies which are expensive and need large assembly areas and a lot of welding. The flow of the process will increase because less die is used, since the process is metal on fluid shaping and not metal on metal. Tool costs will be reduced by at least 40% because the fluid replaces half of the tooling that would be needed with welding and stamping techniques.

New capabilities for hydroforming are being found every day, as engineers learn where and how to apply tube hydroforming for best use. As a result, hydroforming is used to make more and more parts. About 15 years ago, 10% of steel in North American vehicles was tubular, while today the percentage has risen to over 16%. Tube hydroforming is steadily gaining in popularity because it lessens capital costs, reduces the number of parts needed, increases and improves structural strength of product, and offers flexibility and design quality that just does not come with welding and stamping techniques. A number of automobile industries have switched from stamping and welding to hydroforming because it is more cost-effective and creates more high-consistency parts.

For more information on tube hydroforming and hydroforming services, please contact us.

Error: Contact form not found.

Leave a Reply