American Hydroformers: How FEA Can Lower Your Costs

To some people, adding an extra step to your production process may sound counter-intuitive; however, if that step is to consider Finite Element Analysis (FEA), then it might not sound so crazy after all. By adding FEA to the mix, chances are high that you will shave both time and expense off your pre-production process and bring your product to the market quickly and efficiently.

How It Works

The Finite Element Method (FEM) uses math (the language of science) to predict potential problems with prototypes and offer practical solutions before physical models are made.

For the vast majority of geometries and problems, these PDEs cannot be solved with analytical methods. Instead, an approximation of the equations can be constructed, typically based upon different types of discretizations. These discretization methods approximate the PDEs with numerical model equations, which can be solved using numerical methods (Comsol).

Therefore, by adding this simple step to your pre-production phase, you could save yourself several rounds of failed prototypes down the road.

Why It Matters

FEA matters because it saves two extremely valuable resources: time and money.

Although we could debate which of those resources is more important during the early stages of production, we could probably all agree that any product or service that helps us save both are worth considering.

This is, perhaps, the greatest selling point for FEA.

How We Can Help

Here at American Hydroformers, we are well versed in the complexities and pressures of the pre-production stage. If you would like more information about the possibilities afforded through FEA, or if you would like to hear more about our specific products and services and how you can benefit from them, please feel free to contact us.

We are standing by at any time to meet your needs.

About American Hydroformers

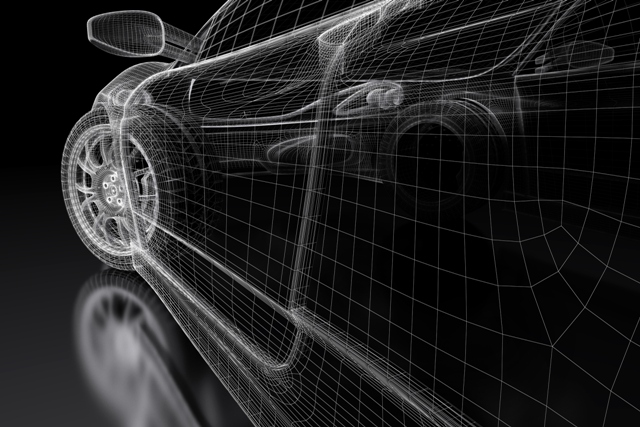

Founded in 2003, American Hydroformers specializes in the tube hydroforming manufacturing process. Production capabilities include numerous metal forming techniques such as hydroforming, hydraulic press work, metal stamping, and tube forming. In addition to hydroformed components, American Hydroformers offers complete assembly level fabrication of automotive structures, robotic welding, and both industrial laser and plasma cutting.

Leave a Reply