Hydroforming Titanium for the Masses?

The advantages of using titanium and titanium alloys have long been apparent to both the scientific and commercial communities:

- Good strength

- Resistance to erosion and erosion-corrosion

- Very thin, conductive oxide surface film

- Hard, smooth surface that limits adhesion of foreign materials

- Surface promotes dropwise condensation

Due to these benefits, titanium and titanium alloys have become important players in a variety of different industries.

Since the introduction of titanium and titanium alloys in the early 1950s, these materials have in a relatively short time become backbone materials for the aerospace, energy, and chemical industries. (The Key to Metals)

However, although there are many advantages to using titanium, its commercial use has been somewhat cost prohibitive. Over the years, manufacturers have instead turned to stainless steel, which although not as durable as titanium, is significantly more affordable to work with.

Until recently, that is.

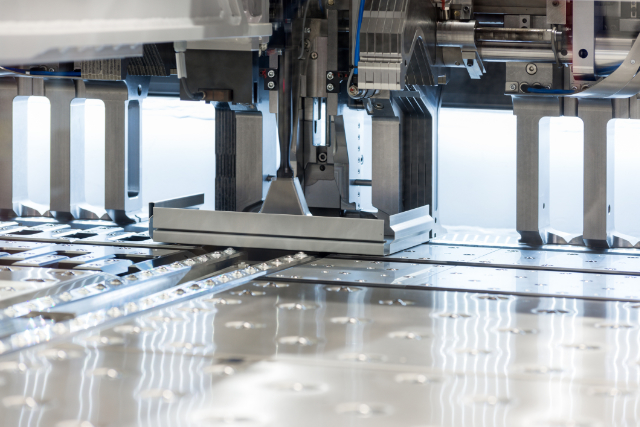

In 2012, it was announced that a team led by André Albert at the Fraunhofer Institute for Surface Engineering “developed a new process for hydroforming titanium at high temperatures in a single step that promises to make titanium more of an everyday material,” a process which allows titanium to be forged by hydraulic pressure in a single step and in one place without cracking (Gizmag). Needless to say, the savings that this new procedure would provide would be an enormous boon to the industry.

With titanium’s exceptional versatility, this new hydroform procedure could move its use from the aerospace industry into everyday life, including window frames, hydraulic lines, jet engine components, bio-compatible implants, and bicycle frames — not to mention the possibilities for the automotive industry, where “because of the lack of cost-effective forming technologies for titanium, currently manifolds, exhaust pipes, catalytic converters and mufflers are primarily manufactured from high-alloy stainless steel” (TechFragments).

With hydroform bringing down the cost of titanium production, perhaps its only a matter of time until more and more of our everyday tasks — cooking, cleaning, grooming, working out — are aided by titanium instruments.

If you have questions regarding developments in hydroform technology and how we can help you take advantage of them, please feel free to contact us.

Error: Contact form not found.

Leave a Reply